Laminex works with some of Australia’s best designers and architects to showcase the creative possibilities of Laminex® laminate. Here we explain how it can be used to make curved shapes and patterns.

Everyone’s familiar with laminate as a material for benchtops, typically in the form of high-pressure laminate (HPL), and for cabinetry, in the form of low-pressure melamine (LPM). Laminex’s collaborative projects highlight that they can be much more than just the flat, rectangular surfaces we’ve come to expect. Laminex HPL can be used to create beautiful curves, organic shapes and decorative patterns that will transform a utilitarian space like a kitchen or meeting room into something special and memorable.

Featuring Laminex Spotted Gum TrueScale™ AbsoluteGrain® (table), Laminex Bluestone (custom door handles), Laminex Brushed Stainless Steel (display shelving), Laminex Kalamata (drawer internals), Laminex Macedon Mist (curved drawers), Laminex Kashmir Granite (display shelving), and Laminex Terril (display shelving).

There are two fabrication methods for creating curved surfaces with laminate: cold-forming and post-forming. The majority of Laminex’s HPL range can be used this way, with each laminate’s thickness influencing the degree of curvature that can be achieved.

Cold-forming

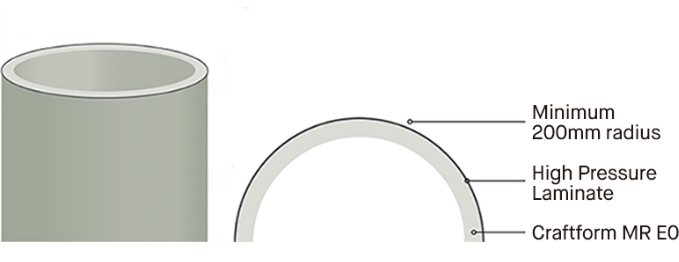

Laminex cold-form illustration. Demonstrating a minimum 200mm cold-form radius. Images are a visual guide only and are not to scale.

Curved surfaces, like the oversized bullnose drawers and interior walls of State of Kin’s cabinetry, are cold-formed. In this process, a curved substrate, such as Trade Essentials Craftform, is fabricated to the desired shape and the HPL is simply adhered directly to the surface. This approach is most useful when designing relatively open-angled curves, with the smallest achievable radius being 150mm, when using Laminex Redback HPL. In some cases, mechanical fastening may be required, to prevent the laminate from springing back into its original shape.

Featuring Laminex Spotted Gum TrueScale™ AbsoluteGrain® (sliding doors & table), Laminex Tasmanian Oak TrueScale™ AbsoluteGrain® (sliding doors), Laminex Bluestone (custom door handles), Laminex Brushed Stainless Steel (display shelving), Laminex Kalamata (drawer internals), Laminex Macedon Mist (curved drawers), Laminex Kashmir Granite (display shelving), Laminex Terril (display shelving), Laminex Classic Flat Architectural Wall Panels in Tasmanian Oak TrueScale™ AbsoluteGrain® & Laminex Spotted Gum TrueScale™ AbsoluteGrain® Finish (dado rail).

Post-forming

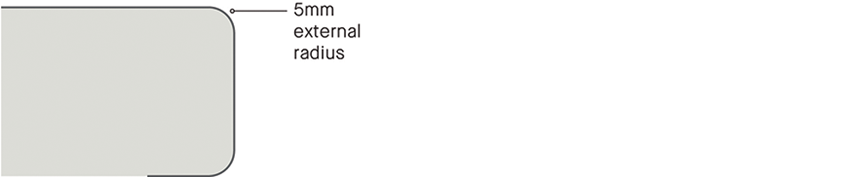

Laminex post-form illustration. Demonstrating a minimum 5mm radius. Image is a visual guide only and is not to scale

The other fabrication technique, post-forming, is used when much tighter curves are required, down to a minimum external radius of 5mm. In this process, the HPL is heated in a post-forming machine, which softens the resins in the laminate sheet and allows it to be bent and conformed to the shape of the substrate. State of Kin’s meeting room demonstrates this perfectly via the bullnose shelving and double-detail dado rails. The bullnose has been synonymous with Laminex for years, but advances in Laminex resin technology has meant even tighter radiuses can now be achieved, opening a new range of creative applications.

Cold-forming and post-forming can only be used for linear curves – that is, the laminate can’t be twisted around more than one axis – and there are different techniques that will achieve different effects. The best way to understand how to bring a curved design to reality is to work with an experienced fabricator.

Making patterns and shapes

Whether small radius or large, Laminex can always be applied with great effect, particularly so when using lifelike decors like those from the Laminex Next Generation Woodgrain collection. But, beyond the curve, different techniques and products can produce extraordinary results.

State of Kin’s sliding doors take factory applied Laminex Tasmanian Oak TrueScale which are then routed in the workshop in preparation for their Laminex Spotted Gum TrueScale stripe panels. Cut precisely to size, the inlays are glued and fixed into place to complete the signature feature. This is where the benefits and accuracy of a CNC machine is most appreciated as this is the best way to achieve a perfectly flat surface over multiple decors.

Featuring Laminex Spotted Gum TrueScale™ AbsoluteGrain® (sliding doors & table), Laminex Tasmanian Oak TrueScale™ AbsoluteGrain® (sliding doors), Laminex Bluestone (custom door handles), Laminex Brushed Stainless Steel (display shelving), Laminex Macedon Mist (curved drawers), Laminex Kashmir Granite (display shelving), Laminex Terril (display shelving), Laminex Classic Flat Architectural Wall Panels in Tasmanian Oak TrueScale™ AbsoluteGrain® & Laminex Spotted Gum TrueScale™ AbsoluteGrain® Finish (dado rail).

For benchtops, or in this case State of Kin’s impressive tabletop, HPL is the recommended product for horizontal surfaces. The boardroom table’s depths and thickness were built up, with the cabinet maker completing the edge and sides with matching HPL. The oversized leg detail at one end was achieved with a slightly different technique. Once the leg was attached by interior fixings to the tabletop, the square ends were all mitred to exacting detail to create a lifelike slab finish that gives the whole table weight and impact. It’s a subtle, but very effective result.

Elsewhere State of Kin have applied HPL on the oversized bullnose drawer fronts inside the cabinets. The desired radius was constructed using a substrate and finished with Laminex Terril. The dado rail that breaks up the Laminex Tasmanian Oak TrueScale walls uses classic Laminex proportions in Laminex Macedon Mist and Spotted Gum TrueScale. It’s tighter radius the perfect use of postformed HPL. This can also be seen in the Laminex Kashmir Granite shelves and the borders that frame the room.

For specific advice, you should contact Laminex directly or speak with your cabinetry supplier.